What is zeolite calcination production line for sale?

The zeolite calcination production line is to continuously calcine ultrafine zeolite powder at 500-700 ℃ to obtain high-purity zeolite catalysts and adsorbents. After calcination in the zeolite calcination production line, the zeolite powder can completely remove the crystal water in the natural zeolite crystal cavity without damaging the zeolite structure, thereby obtaining a highly active zeolite powder product. This zeolite calcination production line can also be applied to other highly active substances that require detachment from crystal water, and its application is very extensive.

|  |

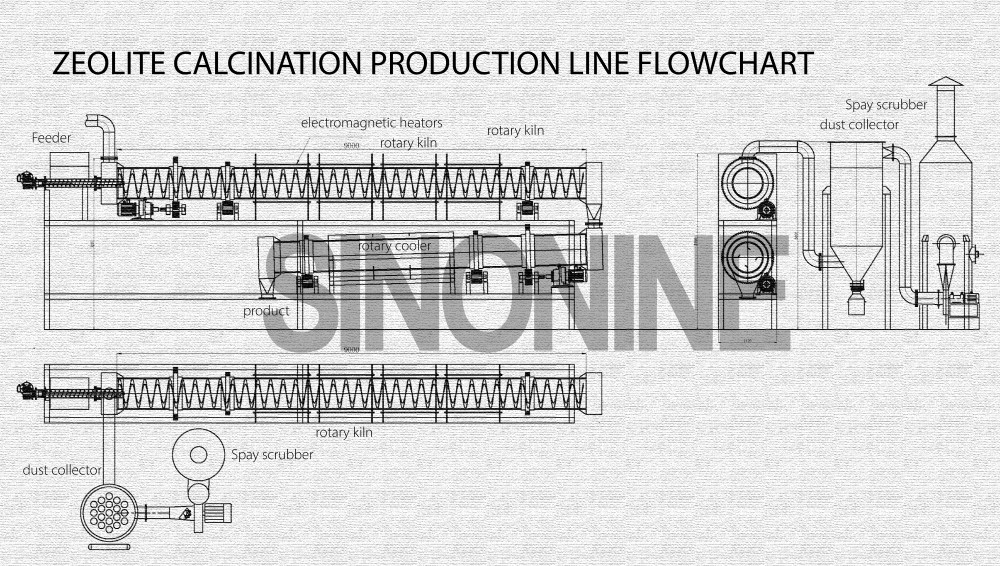

The zeolite calcination production line adopts an electromagnetic rotary kiln as the main equipment and uses electromagnetic heating to effectively protect the zeolite from any fuel pollution. The complete zeolite calcination production line is composed of electromagnetic heating rotary kiln combined with feeding device, dust removal device, cooling machine, etc. The following is the flowchart of the zeolite production line.

Features of zeolite calcination production line

1.High temperature process

Electromagnetic calcination rotary kiln can be used for high-temperature treatment of materials. The equipment is capable of providing a high-temperature environment to achieve the required high-temperature conditions for deformation or chemical reactions of materials such as ores.

2.Accurate temperature control

The electromagnetic calcination rotary kiln can achieve precise temperature control, making the temperature distribution uniform and adjustable. This is very important for strict process requirements to ensure stable product quality and performance.

3.High operational efficiency

The electromagnetic drying and calcination rotary kiln has the characteristics of stable operation, high efficiency, and fast control reaction, which can quickly provide the required heating power and temperature changes. This enables the heating process to reach the target temperature more efficiently, improving production efficiency and reducing operating costs.

4.High energy utilization efficiency

Compared to traditional heating methods such as gas, electromagnetic heating directly converts electrical energy into thermal energy without the need for heat transfer during combustion, reducing energy waste.

5.Less environmental emissions

Electromagnetic heating uses electricity as a power source and does not produce combustion emissions, thus reducing exhaust emissions and smoke production, meeting the requirements of modern industrial development for energy conservation and environmental protection, and helping to improve air quality in the workplace.

6.High degree of mechanization, large production capacity, low resistance of fluid passing through the cylinder, low functional consumption, strong adaptability to material characteristics, and can be customized according to process requirements to meet heating requirements.

+86-25-58875679

+86-25-58875679 +86-18118821087

+86-18118821087