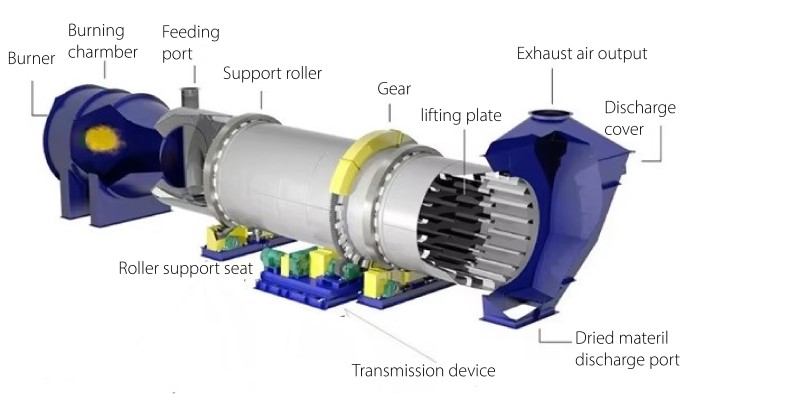

What is a rotary dryer for sale?

Rotary dryer for sale is a type of single cylinder rotary dryer with a long rotary drum. It can be divided into metal pellets dryer, oxide pellets dryer, nickel and iron reduction dryer, coal dryer according to different conditions of temperature equipment, material ratio and overall process. The single drum rotary dryer are mainly used in beneficiation, metallurgy, cement, chemicals, coal and other dry products industry which is currently the preferred product drying equipment. Rotary dryer is the most widely used drying equipment in current market.

How does a rotary dryer work?

The work principle of a rotary dryer is following

The material with moisture is fed into the cylinder of rotary dryer through the feeding port and evenly enters the cylinder. The wet material is then thrown by the lifting device to form a uniform end fabric curtain layer, which mixes and exchanges with the high-temperature air entering. Due to the rotation and inclination of the rotary dryer, the material flips in the circumferential direction and moves in the axial direction.

The material is continuously lifted and scattered by the lifting plate. The material and air move in the rotary dryer cylinder while contacting the hot air flow and chain for heat exchange, causing the moisture of the material to evaporate and gradually be dried. The air temperature gradually decreases, and the dried material is discharged from the lower end.

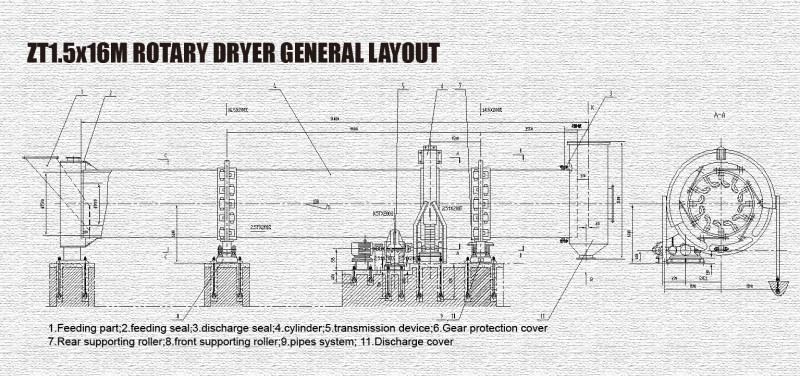

Below is the layout of ZT1.5x16m rotary dryer.

Advantages of rotary dryer for sale

1.The roller of rotary dryer machine is made of light plate stainless steel which has excellent heat resistance, the inner-wall smooth, can reduce the materials' wear and tear.

2.Efficient radiator, and with a reasonable lead air duct, so that the hot air can direct contact with materials, greatly improving the drying efficiency, while saving energy.

3.Using computer control, we can set different rotary drying temperature and rotary drum drying time according to the drying requirements.

4.Major diameter material entrance facilitates the inlet and outlet of materials and greatly improves the drying efficiency.

5.High drying capacity, stable performance, low energy consumption, high productivity.

|  |

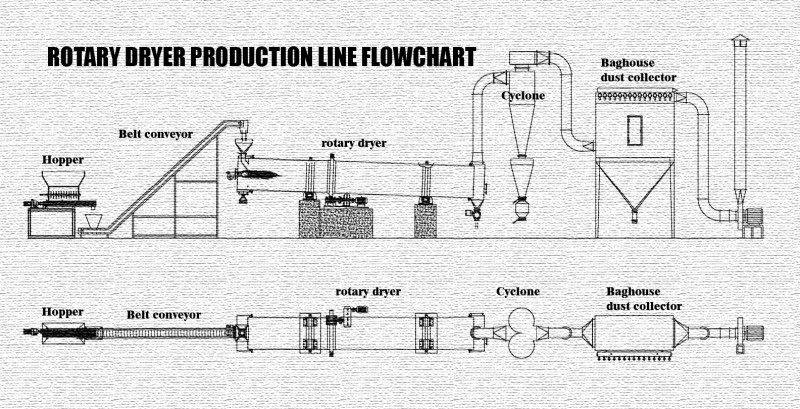

A whole rotary dryer for sale production line

A whole rotary production line consists of rotary dryer, belt conveyor, feeding hopper, dry material belt conveyor, dust collector etc.

The following is a commonly used rotary dryer production line flowchart.

How to select a suitable rotary dryer?

There are several tips for you as reference when you select a set rotary dryer:

1.The raw material will be dried

It is an important factor to be considered of the material features in the rotary dryer. Because different factors are considered for drying different raw materials.

2.The raw material water content in percent

The original water content of the material determines the amount of energy consumption and also affects the operation of the rotary dryer. For materials with high moisture, we recommend physical dewatering first and then drying to save energy.

3.Product water content requirement

The min water content from rotary dryer can reach below 0.5%, less moisture means longer drying time and heat consumption. We need to understand the appropriate moisture requirements for the final product in order to configure the appropriate model of rotary dryer.

4.Heating resource and fuel

The t rotary dryer requires a heat source to complete the drying process, so it is necessary to understand the type of heat source. Fuel options include natural gas, LPG gas, coal, diesel, heavy oil, gasoline, biomass etc.

|  |

5.The material drying temperature needed

The temperature that materials can withstand is different, and we need to understand the temperature that materials can withstand, which can ensure the drying effect and avoid material damage due to high temperature.

6.The capacity

That means how many cubic meters or tons per hour you want this rotary dryer to process. Based on the capacity, we will decide small rotary dryer or large rotary dryer is suitable for you.

7.Ambient temperature

The work performance of rotary dryer will be affected if the working ambient temperature is too low. The rotary dryer for sale will be equipped with bigger volume cylinder or larger burner to compensate for heat loss.

8.Does it need to configure a cooler or not?

The materials dried by the rotary dryer are at high temperatures, and it is necessary to arrange whether to cool them according to actual needs. If cooling is required, we will provide a cooling machine or cooling device for the rotary dryer production line.

|  |

FAQ for rotary dryer

1. I need to use this rotary dryer for sawdust, is it suitable or not?

Yes, it is the best choice for the sawdust drying. For the sawdust, it is light and needs low temperature, the sawdust particle will stay long time in the rotary dryer cylinder, it will be completely dried after discharged.

2. Can I use this rotary dryer for high purity silica sand ?

Yes, it is. For silica sand, we need adopt high temperature drying process and using stainless steel cylinder to avoid iron pollution, the rotary dryer is good choice.

3. How to deliver the rotary dryer?

It depends on different models. Diameter below 2m and length below 12m, it can be loaded to container, if longer and bigger diameter, we will depart the cylinder and put in the FR flat container for delivery.

4. How long the warranty period for the rotary dryer?

Normally speaking, it is 12 months after installation and commissioning, but we will provide future service for whole life of the rotary dryer.

|  |

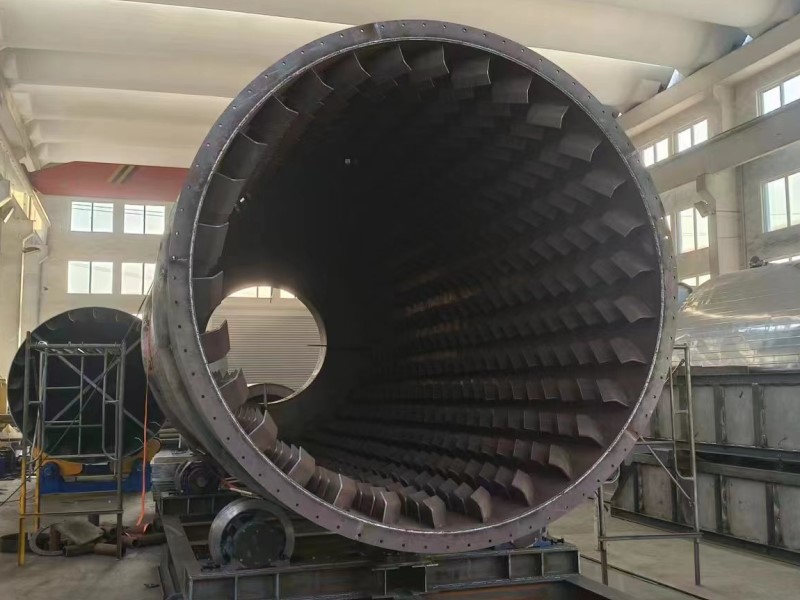

Rotary dryer manufacturing

Sinonine selects high-quality raw materials and accessories, adopts advanced processing technology, and ensures that every rotary dryer has high quality. From design, raw material selection, manufacturing, debugging, every step is meticulously carried out to complete excellent drying operations.

|  |

|  |

Rotary dryer goods Delivery

Based on good quality and decades of experience, the rotary dryer which is manufactured by Sinonine was exported to different countries. The rotary dryer will be packed and loaded in our factory, and then be shipped to our clients safe and sound.

|  |

|  |

Specification of rotary dryer

Model | Cylinder diameter (mm) | Cylinder (mm) | Capacity (t/h) | Rotary Speed (r/min) | Cylinder Inclination (%) | Power (kw) | Weight (t) |

ZT1.0×10 | Ф1000 | 10000 | 1-4 | 1.1-6 | 5 | 7.5 | 7.85 |

ZT1.2×12 | Ф1200 | 12000 | 3-7 | 1.2-6.5 | 5 | 11 | 13.3 |

ZT1.5×12 | Ф1500 | 12000 | 6-9 | 1.4-7 | 5 | 15 | 18.6 |

ZT1.5×14 | Ф1500 | 14000 | 7-10 | 1.4-7 | 5 | 15 | 17.9 |

ZT1.6×14 | Ф1600 | 14000 | 8-11 | 1.4-7 | 5 | 15 | 18.6 |

ZT1.8×14 | Ф1800 | 14000 | 9-13 | 3.5-6.5 | 5 | 15 | 20.85 |

ZT2.0×14 | Ф2000 | 14000 | 11-16 | 2.2-7.4 | 5 | 18.5 | 23.2 |

ZT2.2×12 | Ф2200 | 12000 | 12-17 | 2.2-7.4 | 5 | 22 | 30.3 |

ZT2.2×14 | Ф2200 | 14000 | 14-20 | 2.2-7.4 | 5 | 22 | 32.23 |

ZT2.4×18 | Ф2400 | 18000 | 21-31 | 2.2-7.4 | 4 | 30 | 45 |

ZT2.4×20 | Ф2400 | 20000 | 23-34 | 2.2-7.4 | 4 | 37 | 54 |

ZT2.4×22 | Ф2400 | 22000 | 26-38 | 2.2-7.4 | 4 | 37 | 58 |

ZT2.6×20 | Ф2600 | 20000 | 28-40 | 2.2-7.4 | 4 | 45 | 60.5 |

ZT2.6×24 | Ф2600 | 24000 | 33-48 | 2.2-7.4 | 4 | 45 | 72.7 |

ZT3.0×20 | Ф3000 | 20000 | 35-54 | 8.4-3.85 | 4 | 55 | 86 |

ZT3.0×25 | Ф3000 | 25000 | 46-64 | 8.4-3.85 | 4 | 75 | 96 |

ZT3.0×28 | Ф3000 | 28000 | 52-74 | 8.4-3.85 | 4 | 75 | 122 |

ZT3.2×25 | Ф3200 | 25000 | 60-80 | 2.4-7.6 | 4 | 90 | 119 |

+86-25-58875679

+86-25-58875679 +86-18118821087

+86-18118821087