What is a rotary klin for sale?

Rotary kiln can be divided into cement kiln, metallurgy chemical kiln and lime kiln according to different materials. Cement kiln is used for making cement clinker and there are dry and wet methods to make cement clinker. Metallurgy chemical kiln is widely used for magnetic roasting of poor iron ore and oxidizing roasting of chrome and nickel in the steel factory; backing high-alumina mine in the refractory material factory; baking chamotte and alumina in the aluminum factory and baking chrome ore and chrome powder in the chemical plant. The Lime Kiln is used for roasting active lime in steel works and ferroalloy plants and light roasting dolomite.

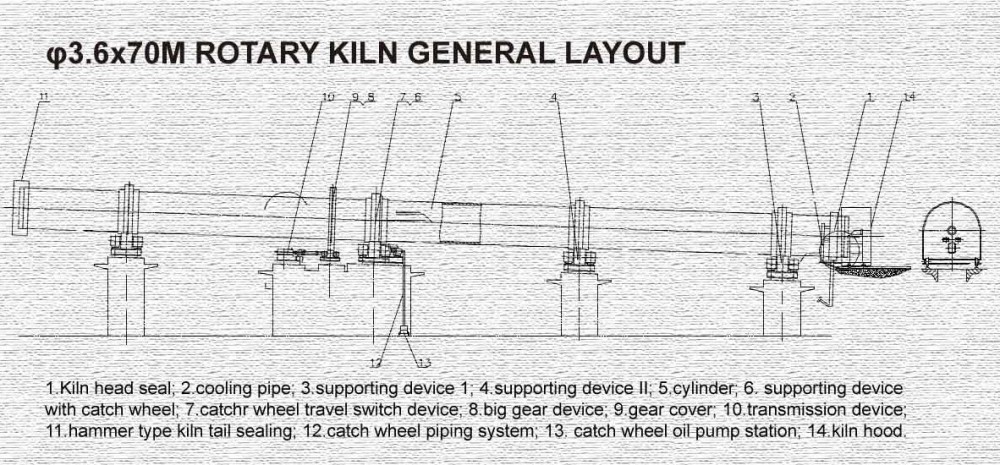

Strcutre of rotary kiln

The rotary kiln is composed of a cylinder body, a supporting device, with gear wheel supporting device, driving device, a movable kiln head, kiln sealing device, coal dust pipe device etc. The kiln body is sloping, the whole kiln body is composed of roller supporting device, and a wheel blocking device controlling the kiln body, transmission system, in addition to setting up the main drive, it is also equipped with auxiliary transmission device to drive the kin body to rotate and prevent the bending deformation of the kiln body in case of the main power source fault, kiln head and tail sealing device adopts advanced technology, to ensure the reliability of sealing.

|  |

Working principle of roatry kiln

Materials enter the kiln fir calcination from the kiln end (the barrel of the high-end). Due to the inclination and slow rotation of cylinder, the materials roll along the circumferential direction and move along the axial direction (from high-end to low-end), to complete the process of decomposition and firing, after physical and chemical changes, clinkers finally enter the cooler by kiln hood. The fuel is sprayed into the kiln from the kiln head, and the waste gas ,after heat exchange with materials, are exchanged from the kiln tail. The layout of 3.6x70m rotary kin is as following.

Features of roatry kiln

1.Advanced slide bearing, set up automatic temperature measuring device and electrical heating device, and equipped with option of rolling bearing.

2.Hydraulic gear wheel device equipped with the advanced hydraulic control system.

3.Using Dc motor or frequency variable motor to control rotational speed, reliable operation, efficient energy-saving

|  |

4.The plate under box tire could be fixed, adjustable and floating, it is of a simple structure, and convenient to maintain and replace.

5.According to the different kiln, a variety of sealing solutions are optional, such as cylinder pressure tight end sealing, spring pressure tight end seal, heavy hammer graphite block seal, spring graphite block seal, fish scale labyrinth seal, axial labyrinth seal and the combination of the above methods, good adaptation and sealing effect to vibrating cylinder .

|  |

|

|

Rotay kiln Goods Delivery

Based on good quality and decades of experience, the rotary kiln which is manufactured by Sinonine was exported to different countries. The rotary kiln cylinder will be divided to several parts,then packed and loaded in flat container of bulk shipment, and then be shipped to our clients project spot.

|  |

|  |

|  |

|  |

Specification of rotary kiln

Model | Capacity (t/d) | cylinder inclination (%) | Support (pcs) | catch wheel Type | cylinder rotary speed(r/min) | Power(Kw) | Weight(t) (exclude refractory material) | ||

Main transmission | auxiliary transmission | Main transmission | auxiliary transmission | ||||||

Φ2.8×44 | 300 | 3.5 | 3 | Mechanical | 0.4-2.2 | 4.75 | 55 | 4 | 177 |

Φ3.0×48 | 600 | 3.5 | 3 | Hydraulic | 0.36-3.4 | 9.36 | 100 | 7.5 | 213 |

Φ3.2×50 | 1000 | 3.5 | 3 | Hydraulic | 0.36-3.6 | 6.5 | 160 | 15 | 281 |

Φ3.3×50 | 1200 | 4 | 3 | Hydraulic | 0.36-3.6 | 5.61 | 160 | 15 | 317 |

Φ3.5×54 | 1800 | 4 | 3 | Hydraulic | 0.39-3.9 | 7.66 | 220 | 18.5 | 341 |

Φ4.0×60 | 2500 | 4 | 3 | Hydraulic | 0.4-4.1 | 8.2 | 315 | 22 | 434 |

Φ4.3×64 | 3500 | 4 | 3 | Hydraulic | 0.4-4.0 | 7.93 | 400 | 30 | 562 |

Φ4.8×74 | 5000 | 4 | 3 | Hydraulic | 0.35-4.0 | 8.52 | 630 | 55 | 854 |

Φ5.0×74 | 6000 | 4 | 3 | Hydraulic | 0.35-4.0 | 7.58 | 710 | 55 | 885 |

Φ5.6×87 | 8000 | 4 | 3 | Hydraulic | Max4.2 | 8.7 | 800 | 90 | 1200 |

Φ6.0×95 | 10000 | 4 | 3 | Hydraulic | Max5.0 | 9.2 | 950×2 | 132 | 1580 |

+86-25-58875679

+86-25-58875679 +86-18118821087

+86-18118821087