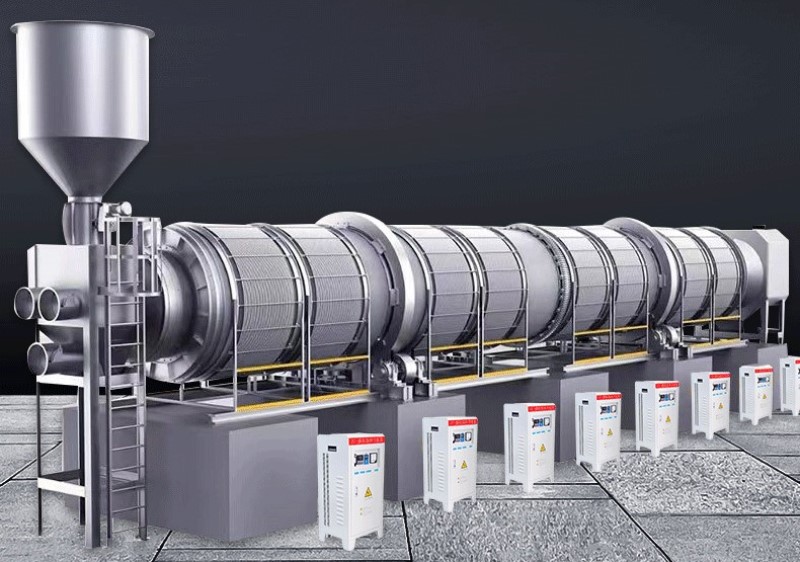

What is a electromagnetic rotary kiln for sale?

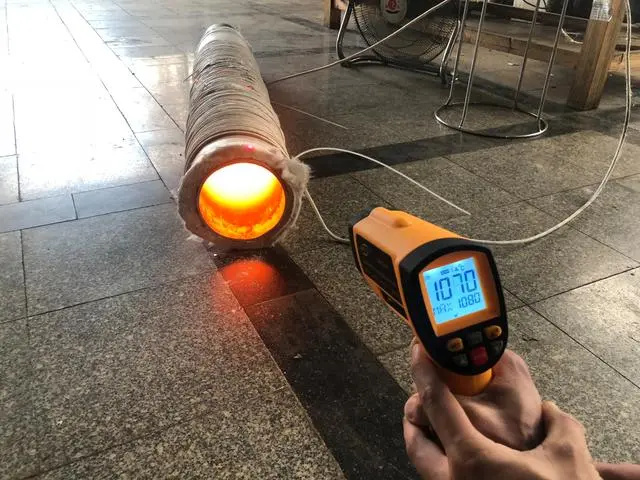

Electromagnetic rotary kiln is a calcination kiln that combines electromagnetic technology and rotary kiln, used for drying and calcining materials. The electromagnetic rotary kiln adopts electromagnetic heating to achieve the required temperature of the materials inside the kiln. The temperature of the electromagnetic kiln can be set arbitrarily within 0-1200 ℃ to achieve batch continuous production.

How a electromagnetic rotary kiln for sale work?

The material is quantitatively fed into the electromagnetic rotary kiln cylinder by the VFD feeder, and the cylinder is slightly inclined and the speed can be adjusted within a certain range. Under the flipping of the plate copying device inside the cylinder, the material is evenly dispersed inside the cylinder and fully contacts with the electromagnetic converted heat energy, thereby achieving the purpose of drying or calcination. After sufficient calcination or drying, the material is discharged from the kiln through the discharge port at the other end of the cylinder to achieve the purpose of drying and calcination.

|  |

Electromagnetic heater is the core component of electromagnetic rotary kiln

The electromagnetic heater generates high-frequency current through a high-frequency power source, which forms a high-frequency alternating electromagnetic field through the coil. When a high-frequency alternating electromagnetic field acts on a magnetic conductor, according to the principle of electromagnetic induction, eddy current effect (also known as Joule heating effect) occurs inside the magnetic conductor. The material inside the magnetic body will generate induced current and generate intense friction with the electrons inside the magnetic body. This intense friction generates frictional heat, thereby converting the energy of the electromagnetic field into thermal energy. When the rotary kiln is filled with materials, the kiln body becomes a magnetic conductor, and the internal materials are heated as the target of thermal conduction by the magnetic conductor.

|  |

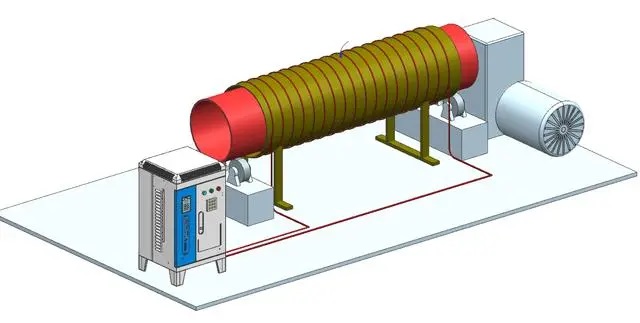

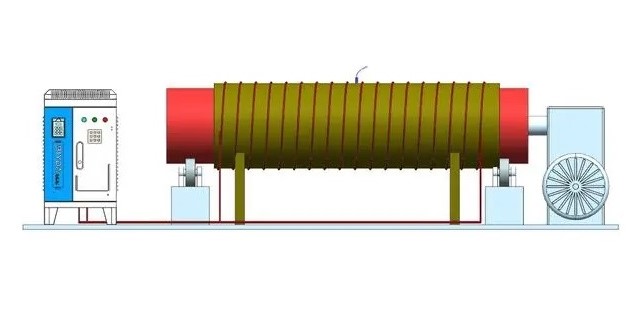

Electromagnetic rotary kiln system

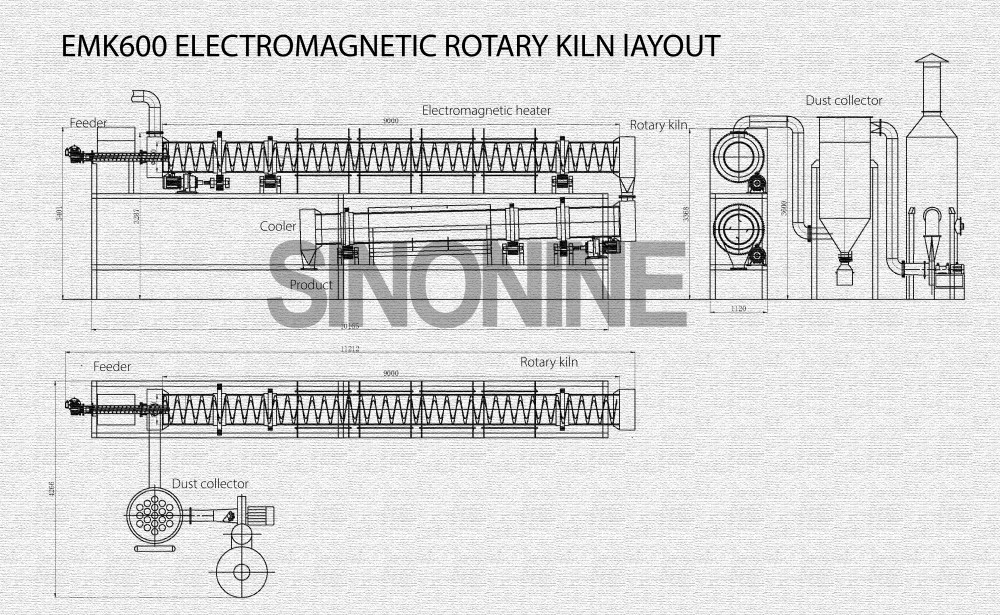

A complete electromagnetic rotary kiln consists of a rotary kiln, electromagnetic heater, feeder, dust collector, etc. If a lower temperature is required for the calcined material, necessary cooling machines need to be equipped. The following is the layout of EMK600 electromagnetic rotary kiln.

Advantages of electromagnetic rotary kiln

Application of electromagnetic induction heating instead of the traditional transfer heating method, because the cylinder is directly active heating, so there are many advantages in the application of electromagnetic heater equipment supporting, summarized as follows.

1.Using electromagnetic induction heating method compared to the traditional electric sun wire or gas heating, heating time can usually be shortened by more than 50%; energy-saving effect can reach at least 30%. At the same time, this heating process without any waste solid emissions, solving the problem of environmental protection and security inspection.

2.Direct active heating, and power density makes heating faster.

3.Kiln cylinder active heating, to avoid the loss of heat transfer and thus the use of more energy efficient.

4.No open flame and heating medium makes the operation safer and the environment cleaner.

5.All digital control system ensures more accurate temperature control and more intelligent equipment.

6.Good independence of equipment, the volume may be smaller, simple maintenance.

|  |

| |

Specification of electromagnetic rotary kiln

Model | Inner cylinder size(mm) | Power(Kw) | Temperature(℃) | Capacity(kg/h) | Angle(°) | Weight(t) |

EMK100 | Ø100×4500 | 36 | 0-1200 | 4 | 0.5-5 | 4 |

EMK150 | Ø150×4500 | 42 | 0-1200 | 8 | 0.5-5 | 4 |

EMK200 | Ø200×4500 | 48 | 0-1200 | 15 | 0.5-5 | 4 |

EMK350 | Ø350×9000 | 68 | 0-1200 | 120 | 0.5-5 | 8 |

EMK400 | Ø400×9000 | 108 | 0-1200 | 150 | 0.5-5 | 10 |

EMK500 | Ø500×9000 | 180 | 0-1200 | 250 | 0.5-5 | 12 |

EMK620 | Ø620×10500 | 260 | 0-1200 | 300 | 0.5-5 | 15 |

EMK700 | Ø700×10500 | 280 | 0-1200 | 360 | 0.5-5 | 18 |

EMK800 | Ø800×10500 | 350 | 0-1200 | 480 | 0.5-5 | 20 |

EMK940 | Ø940×12000 | 400 | 0-1200 | 650 | 0.5-5 | 25 |

EMK1000 | Ø1000×12000 | 410 | 0-1200 | 750 | 0.5-5 | 28 |

EMK1100 | Ø1100×12000 | 460 | 0-1200 | 900 | 0.5-5 | 30 |

EMK1250 | Ø1250×12000 | 500 | 0-1200 | 1000 | 0.5-5 | 35 |

EMK1420 | Ø1420×13500 | 600 | 0-1200 | 1350 | 0.5-5 | 40 |

EMK1500 | Ø1500×13500 | 750 | 0-1200 | 1500 | 0.5-5 | 45 |

EMK1600 | Ø1600×15000 | 900 | 0-1200 | 1600 | 0.5-5 | 50 |

EMK1800 | Ø1800×15000 | 1000 | 0-1200 | 1900 | 0.5-5 | 55 |

EMK2000 | Ø2000×15000 | 1100 | 0-1200 | 2200 | 0.5-5 | 60 |

EMK2200 | Ø2200×15000 | 1300 | 0-1200 | 2600 | 0.5-5 | 70 |

+86-25-58875679

+86-25-58875679 +86-18118821087

+86-18118821087