What is a hollow paddle dryer for sale?

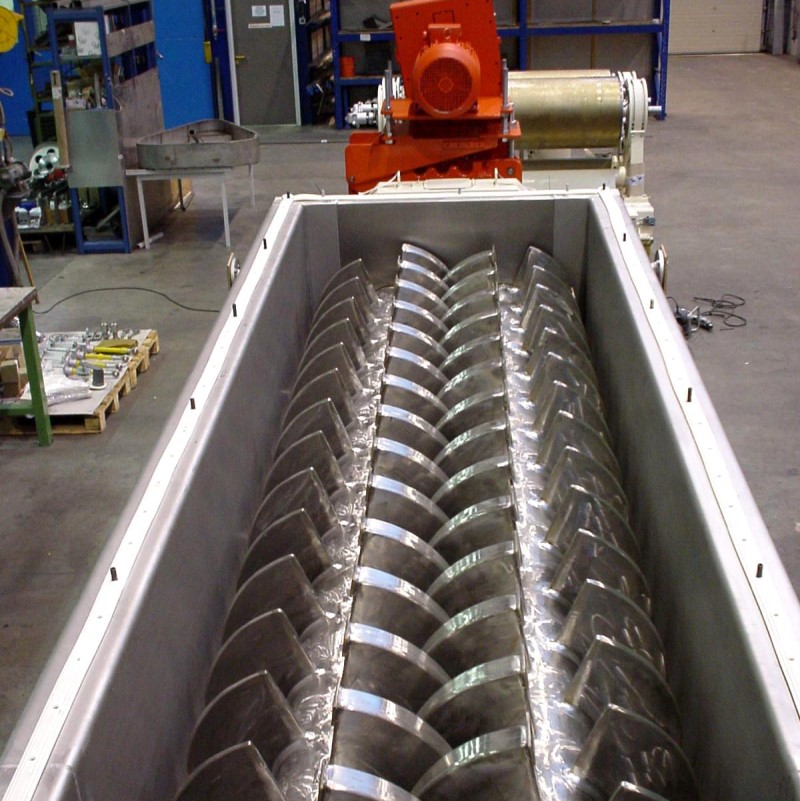

Hollow paddle dryer is an indirect low temperature heating dryer used to dry sludge, pigment etc.It consists of a W-shaped shell with a jacket end face, an upper cover, two hollow shafts with blades, end covers at both ends, a rotating joint with a medium, a metal hose, and a transmission mechanism including gears and sprockets.

The product can indirectly heat or cool paste, granule, powder and slurry materials, and can complete the unit operation of drying,cooling, heating, sterilizing, reacting, low temperature combustion and so on. The special wedge-type stirring heat transfer slurry blade in the equipment has high heat transfer efficiency and self-cleaning function of heat transfer surface.

|  |

Working principle of hollow paddle dryer

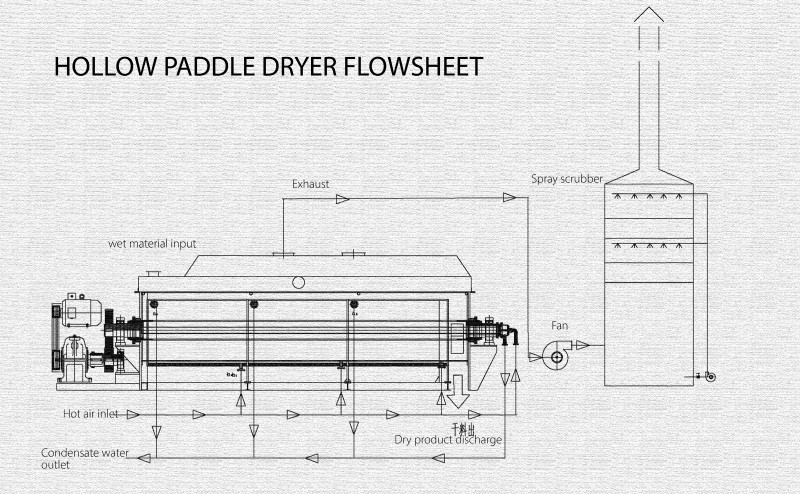

Densely lined with wedge-shaped hollow shaft hollow blades, heat medium through the hollow axial flow through blades. Uniteffective volume of a very large area of heat transfer, heat medium temperature from -40 ℃ to 320 ℃, can be water vapor, may also be liquid-type: such as water, oil and so on. Indirect conduction heating, the air does not carry away the heat, the heat are used to heat materials. Only through the device body heat loss to the environment, heat insulation layer. Wedge-shaped blades with self-cleaning heat transfer surfaces. Wedge-shaped surface material particles and scrubbing effect relative movement, to wash away the wedge surface material attachments. so in operation have maintained a clean heat transfer surfaces. Blade dryer for the W-type shell, the shell of the general arrangements for 2- hollow stirring shaft. Shell with a sealed cover with the cover to prevent dust leakage and collection of materials, solvent vapor materials Set out and exit pull a block, to ensure a high degree of material level, so that heat transfer surface is covered with fully materials.Heat medium through the rotary joint, passing through the shell jacket and the hollow stirring shaft, hollow shaft stirring according to the type of therma media have different internal structures to ensure the best heat transfer.

Features of hollow paddle dryer

1.Blade dryer energy consumption is low: as indirect heating, the air does not carry away a lot of heat insulation of dryer wall has, on the slurry material. evaporation of 1kg of water vapor only 1.22kg of steam.

|  |

Specification of hollow paddle dryer

Model | heat transfer area(m²) | number of axles | motor power(kw) | spindle speed(r/min) | Dimension(mm) |

KJG-4 | 4 | 2 | 3~3.5 | 1.5~15 | 3300x800x800 |

KJG-6 | 6 | 2 | 4~75 | 1.5~15 | 3500x900x1200 |

KJG-8 | 8 | 2 | 5.5~11 | 1.5~15 | 3900x900x1200 |

KJG-10 | 10 | 2 | 7.5~11 | 1.5~15 | 4000x1250x1450 |

KJG-15 | 15 | 2 | 7.5~11 | 1.5~15 | 5200x1400x1720 |

KJG-20 | 20 | 2 | 11~15 | 0.5~10 | 5500x1700x1800 |

KJG-25 | 25 | 2 | 15~22 | 0.5~10 | 6000x1700x1900 |

KJG-30 | 30 | 2 | 15~30 | 0.5~10 | 6000x2000x200 |

KJG-40 | 40 | 2 | 22~35 | 0.5~10 | 6500x2000x2000 |

KJG-60 | 60 | 2 | 35~55 | 0.5~10 | 8150x2150x2400 |

KJG-70 | 70 | 2 | 35~75 | 0.5~10 | 8400x2500x2600 |

KJG-80 | 80 | 2 | 35~75 | 0.5~10 | 9000x2500x2600 |

KJG-100 | 100 | 2 | 55~75 | 0.5~10 | 9300x3000x2700 |

KJG-120 | 120 | 4 | 70~110 | 0.5~10 | 8150x4000x2400 |

KJG-160 | 160 | 4 | 70~150 | 0.5~10 | 9000x4500x2500 |

KJG-200 | 200 | 4 | 110~150 | 0.5~10 | 9300x5500x2700 |

KJG-240 | 240 | 5 | 140~220 | 0.5~10 | 9300x5850x2700 |

KJG-250 | 250 | 6 | 150~225 | 0.5~10 | 9300x6500x2700 |

KJG-300 | 300 | 6 | 165~225 | 0.5~10 | 9300x8000x2700 |

+86-25-58875679

+86-25-58875679 +86-18118821087

+86-18118821087