What is calcination production line for sale?

Calcination production line is a complete production line to calcination various types of solid and powder material. Its functions can be divided into calcination kiln, atmosphere kiln, closed vacuum kiln, activation kiln, volatilization and separation kiln, drying kiln, etc.

The main components of calcination drying production line

For a calcination production line for sale, it contains the following parts.

Materials feeding device system

Raw materials enter the rotary kiln through various methods to complete the quantitative feeding operation.

Rotary kiln

According to different raw materials, different structures of rotary kilns are used, and the cylinder material can be carbon steel, stainless steel, or special materials. The heating method can be direct heating or indirect heating. The diameter, length, speed, and inclination of the cylinder should be determined based on the capacity of the calcination production line, the residence time of the material, and the calcination temperature.

Heating device

The heating of the rotary kikn should be arranged with a reasonable heating system, which can use various fuels such as electricity, natural gas, diesel, coal, biomass, etc. The heating system should be arranged reasonably and controlled automatically.

Exhaust gas treatment device

The exhaust gas generated by calcination has a high temperature and is accompanied by various harmful substances. It needs to be equipped with dust collectors, scrubbing device and other devices to clean the exhaust gas before being discharged into the atmosphere.

Cooling machine

The dried material has a high temperature. If there is a cooling requirement, a cooling machine should be arranged after calcination to reduce the high-temperature material to a reasonable temperature. The cooling machine can be air-cooled or water-cooled.

Automatic control system

The calcination production line should be equipped with an automatic control production line for detecting the production process, adjusting the calcination temperature, adjusting the cylinder speed, and monitoring the entire production process.

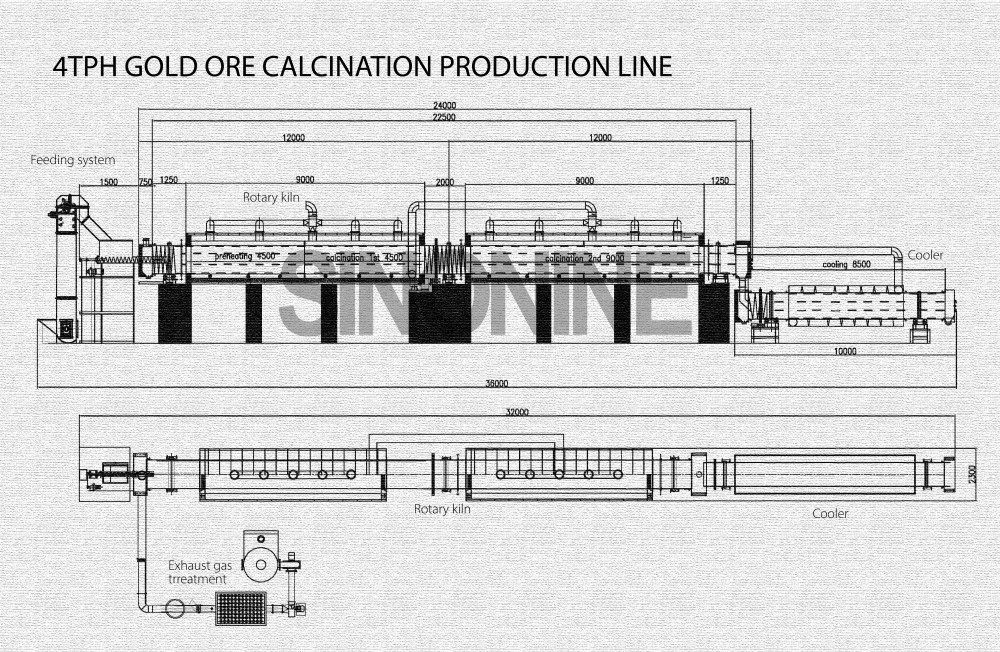

The following is a typical layout of a 4tph gold ore concentrate calcination production line

Calcination production line application

Calcination production line application

Calcination, often referred to as thermal processing, involves heating a specified material to a specific temperature in order to cause thermal decomposition.

1. Calcination kiln

Calcination is an important material processing technique primarily used to alter the physical and chemical properties of materials.

2. Atmosphere kiln

According to the characteristics and requirements of the calcined material, control the atmosphere inside the furnace, such as oxidizing atmosphere, reducing atmosphere, or inert atmosphere. The control of atmosphere can be achieved by adjusting the ratio of fuel and air, and introducing specific gases.

3. Closed vacuum kiln

It is a device used for high-temperature treatment in a relatively enclosed environment, which can accurately control parameters such as oxygen content and pressure inside the kiln, creating an ideal environment for specific process.

4. Activation kiln

By activating materials, their activity and reactivity can be improved, and they are widely used in fields such as activated carbon production, molecular sieve activation, and catalyst activation.

5. Volatile Separation Kiln

Used for processing specific materials, utilizing the differences in volatilization characteristics of different components in materials under high temperature environments, to make specific components evaporate and separate from other components. In the kiln, materials are heated to a certain temperature, and volatile components are transformed into gas under high temperature, and then carried out of the kiln through specific airflow or other means, while non-volatile components remain in the kiln or form specific products.

6. Drying kiln

It is a device used to remove moisture from materials by heating air or other gases to circulate in the kiln and exchange heat with the materials, thereby evaporating the moisture in the materials.

Commonly Calcined Materials

-Advanced Ceramics

-Alumina Ceramics

-Bauxite

-Calcium Carbonate

-Catalysts

-Dolomite

Glass Materials

-Gypsum

-Hydrotalcite

-Kaolin

-Limestone

-Phosphate Ore

-Silica

-Specialty Chemicals

-Zeolites

-Zinc Carbonate

-Gold ore concentrate

Directly Heated Vs Indirectly Heated calcination production

Direct-Fired calcination production

In a direct-heat rotary kiln, the material being dried comes into direct contact with a stream of heated gases. The hot gases may be combustion gases that are mixed with air, clean air that has been heated, or some other specialty gas. The material being dried or calcined is fed into one end of the rotating drum and is lifted by internal flights to cause it to cascade through the stream of hot gas. The drum is angled down on the discharge end which moves the material gradually toward that end of the drum. The gas stream can enter the drum from either end. If it enters at the feed end of the drum, it is known as a direct-fired co-current rotary kiln, and if the gas enters at the discharge end then it is a direct-fired counter-current rotary kiln.

Indirect-Heat calcination production

For various reasons, some products dried in a rotary kiln require special conditions that cannot be met by a direct-heat rotary kiln. For example, more control of the atmosphere within the kiln/dryer to promote oxidation or reduction may be required. The material may be extremely fine or need to be handled more gently. For other processes like drying food, preventing contamination of the product is important. Each of these issues can be addressed by the use of an indirect-fired rotary drum kiln. For this type of rotary kiln, the heat for calcination/drying is applied to the shell of the drum. This may be accomplished by steam jacketing, oil heating, or furnace encasement of the rotary drum.

An indirect-fired rotary kiln also has specialized flights within the drum. These flights are included to provide enough agitation of the material to promote efficient heat transfer. Because the shell itself is heated, the gas velocities within the drum are lower and the size of the gas handling system is smaller.

+86-25-58875679

+86-25-58875679 +86-18118821087

+86-18118821087