What is a gold ore calcination production line for sale?

The gold ore calcination production line is used to calcine gold ore concentrate or tailings at high temperatures, thereby removing impurities such as sulfides from the concentrate and creating reasonable conditions for the recovery of useful minerals. This gold ore calcination production line can greatly improve the recovery rate of gold ore and is also widely used in the calcination and purification of silver, copper, and precious metal ores.

|  |

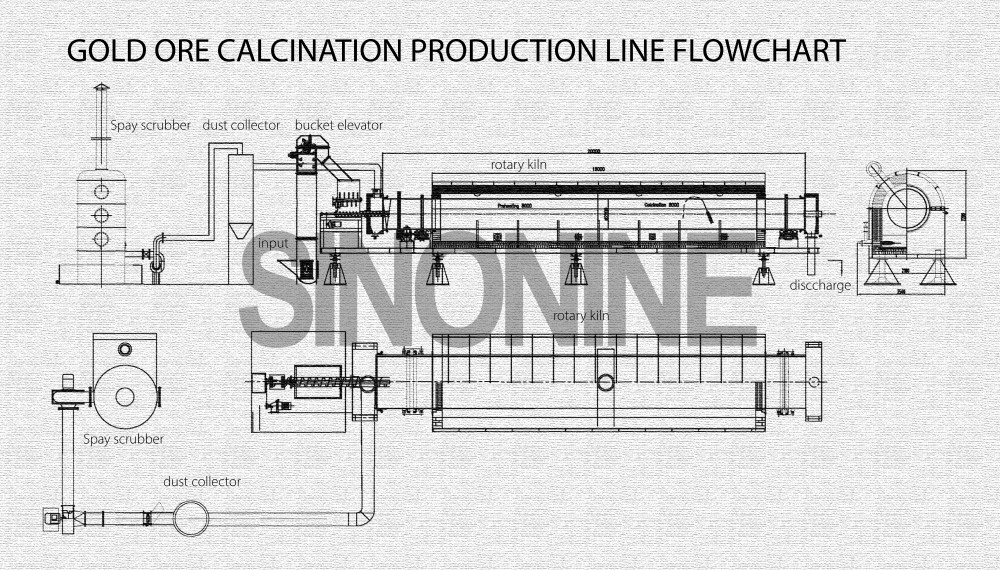

The gold ore calcination production line adopts indirect heating rotary kiln as the main equipment. The rotary kiln is made of high-temperature and corrosion-resistant SUS310S material, and the calcination temperature can reach 1250 ℃. The calcination heat source adopts burners system arranged outside the insulation room of the rotary kiln, which can use natural gas, diesel, gasoline and other fuels. The calcination tail gas is treated and recovered using a spray scrubber, and after being cleaned, it is discharged into the atmosphere. The following is a typical flow chart of a 1tph gold ore calcination production line.

Features of gold ore calcination production line

1.The gold ore calcination kiln has compact structure and good sealing effect, which reduces material loss and heat loss.

2.Automatic temperature control, segmentation setting, over-temperature alarm, long kiln lining life, uniform wall temperature distribution in each zone, temperature control accuracy ≤ ± 5 °C.

3.The fuel combustion is sufficient, the heat transfer efficiency is high, the heat preservation performance is good, and the surface temperature rise of the equipment does not exceed 50 °C.

4.The thermal efficiency of the burner is >99%, the single-pass thermal efficiency of the roaster is more than 40%, the flame of the burner is columnar or flat, straight and powerful.

5.The gold ore calcination production line has a compact structure, small footprint, and low equipment investment.

+86-25-58875679

+86-25-58875679 +86-18118821087

+86-18118821087