What is the sand drying production line for sale?

Sand drying production line for sale is a complete production line to dry various types of sand such as river sand, sea sand, frac sand, foundry sand, casting sand, garnet sand, mortar sand, glass sand, glassware sand ,bottle glass sand, water filter sand, high purity silica sand etc.

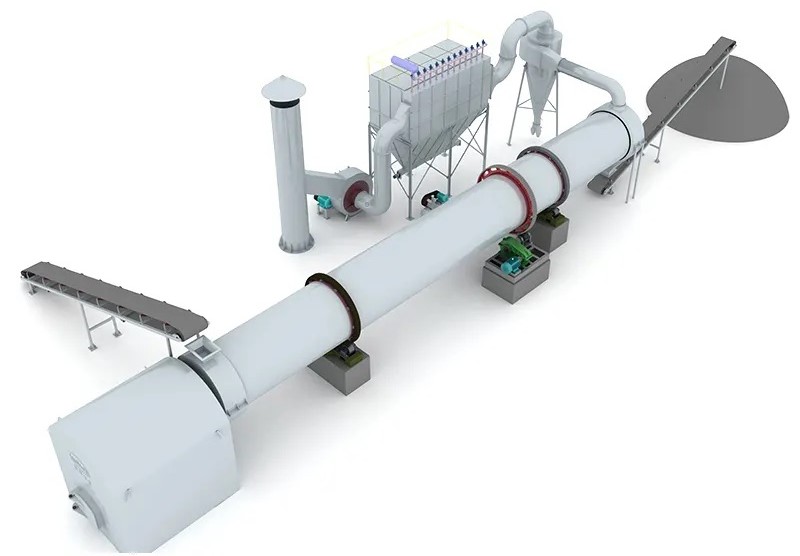

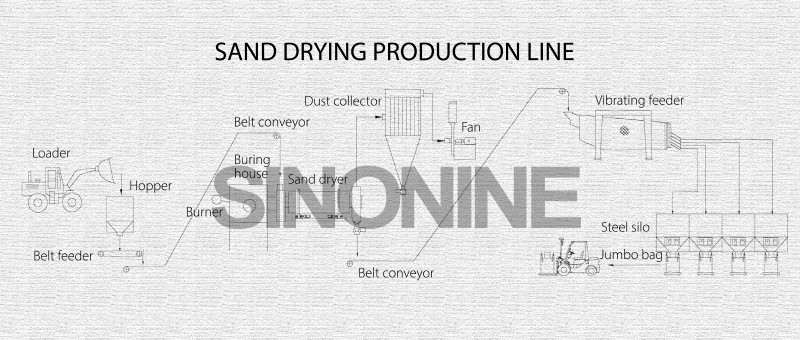

The wet sand will be fed to sand dryer and reduce the water to below 1% or less to meet kinds of application. The whole sand drying system procedure is controlled by automatic PLC control cabinet, and can start automatic operation with one click, the following is a typic flowchart of sand drying production for sale.

The main components of sand drying production line

For a sand drying production line for sale, it contains the following parts.

Wet Materials Hopper

The wet sand will be loaded in the wet materials hopper, the hopper equip with a belt feeder, it will feed the sand material in to sand drying production line evenly. The hopper is special designed and enable no remaining material at four corners.

|  |

Wet Material Belt Conveyor

The belt conveyor will feed the raw wet sand directly to the sand dryer, the belt conveyor is often placed at a 16 degree angle and run smoothly.

Burner

The burner provide heat source for the sand drying production and can use fuels such as diesel, gasoline, natural gas, coal, biomass etc.

|  |

Burning Chamber

Function: The combustion chamber is made of high temperature resistant refractory material. The combustion burning chamber is resistant to high temperatures and has a long life.

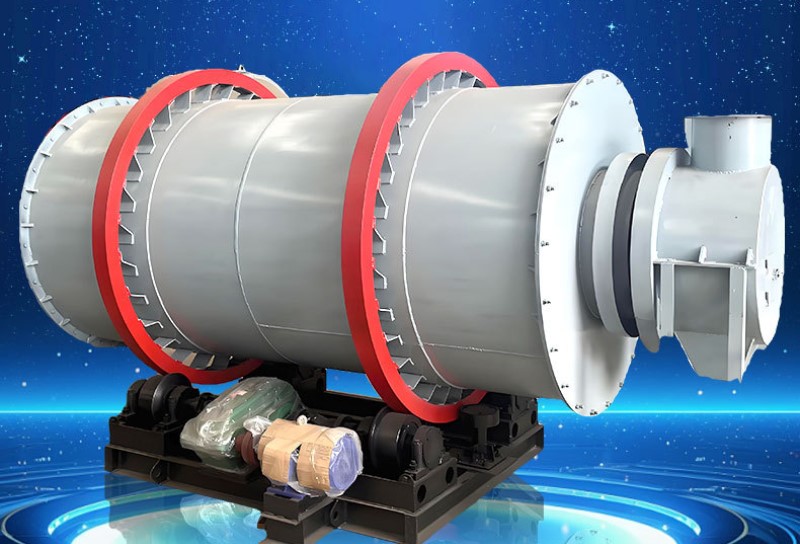

Sand Dryer

The main equipment of sand drying production line is a three cylinder rotary dryer or a single drum rotary dryer, The sand dryer has high thermal efficiency, energy saving and environmental protection. It adopts a unique structural design and can adapt well to the features of sand to complete the drying task.

|  |

|  |

Discharge hopper

The discharge hopper will discharge the dried sand out of the sand dryer, it can reduce the air loss of the induced air system and increase the drying output, Precisely monitor and control the materials temperature and effectively take advantage of heat.

Dust Collector

The dust generated during the sand drying process should be removed by dust collectors, which is generally composed of a cyclone and a baghouse dust collector. It can effectively absorb all the dust and has the characteristics of high temperature resistance and easy cleaning. It is an essential component of the sand drying production line.

Dry Material Belt Conveyor

The dried materials are transported by a belt conveyor to the outside of the sand dryer, which can prevent slip and high temperature, ensuring the smooth operation of the sand drying production line.

Vibrating Screen

The vibrating screen is used to grade the dried sand, remove oversize particles of sand or divide them into finished products with different particle size ranges.

Packing system

The packing machine can package the dried sand into jumbo bags from 500-1500kg or small bags 20-50kg. Different specifications of bags can be matched with different packaging systems.

|  |

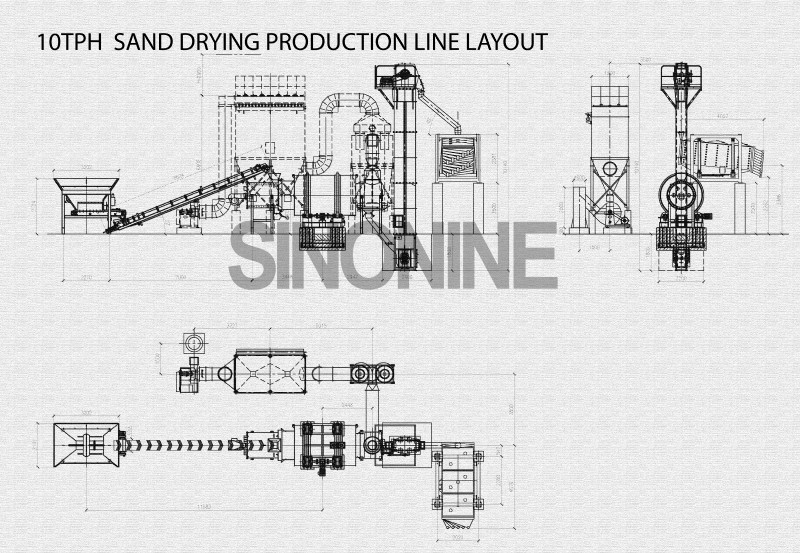

Sand drying production line layout

The capacity of sand production line can be from 1-100tph for single line, Sinonine can design a production line based on the type of sand, output, and finished product requirements, and provide a detailed design layout. The following is the layout of a 10 tph sand drying production line.

Sand drying production line manufacturer

There are several sand production line manufacturers in China. As one of them, Sinonine is a manufacturing enterprise specializing in the production of sand drying production line and rotary dryers. Our machines have passed the ISO certification and are exported to developed countries such as Africa, Asia, America, Europe etc.

+86-25-58875679

+86-25-58875679 +86-18118821087

+86-18118821087