What is a sludge drying production line for sale?

The sludge drying production line is used to dry sludge with a certain viscosity. It uses indirect heating to remove the moisture from the sludge and obtain dried products. It is widely used for drying urban domestic sludge, papermaking sludge, electroplating sludge, prevention and control sludge, mineral sludge and other viscous materials. The sludge drying production line adopts a hollow paddle dryer as the main equipment, matched with feeding conveying and air treatment equipment, to form a complete sludge drying production line.

|  |

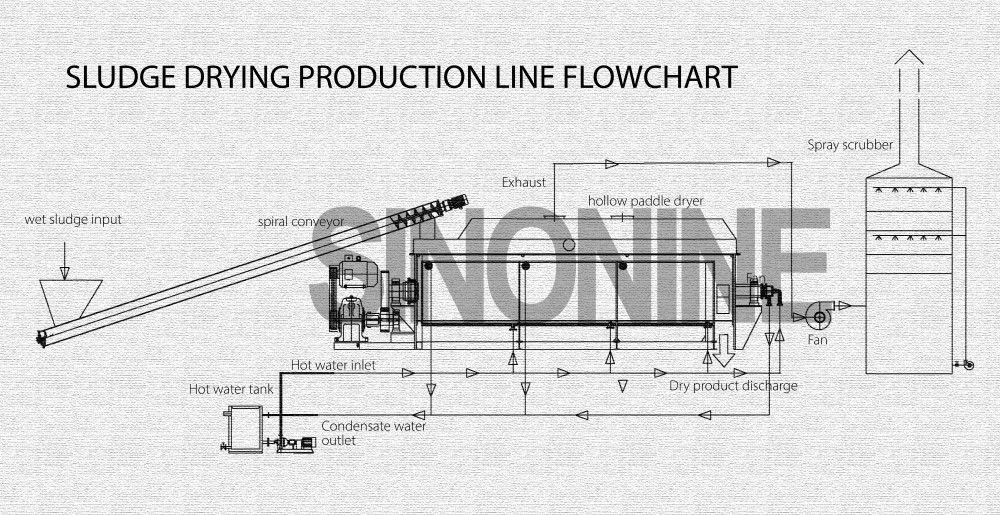

Sinone has rationalized the design of the hollow paddle dryer and adopted a unique structure, which is suitable for drying various sludge operations. This sludge drying production line has become the most popular production line currently. The following is a typical sludge drying production line flowchart.

Features and advantages of sludge drying production line

1.Drying energy consumption is low

as indirect heating, the air does not carry away a lot of heat

2. Low cost

Within the effective volume of units have a large heat transfer surface, the reduced processing time, equipment size becomes smaller. Would greatly reduce the building area and building space.

3.Environmental pollution

The sludge drying production line do not carry air, dust entrainment few materials. To have contaminated materials or be recycled solvent conditions, can be used closed circuit.

4.Low operating cost

The sludge drying production line normal operation 1-2 persons/day. Low speed and reasonable structure, wear very low maintenance costs.

5.Operation stability

As the wedge-shaped blades of special compression - expansion of stirring, so that material particles sufficient surface contact with the heat transfer in the axial zone, the material temperature, humidity, mixed density gradient is very small, thus ensuring the process stability.

+86-25-58875679

+86-25-58875679 +86-18118821087

+86-18118821087