What is a vibrating fluidized bed dryer for sale?

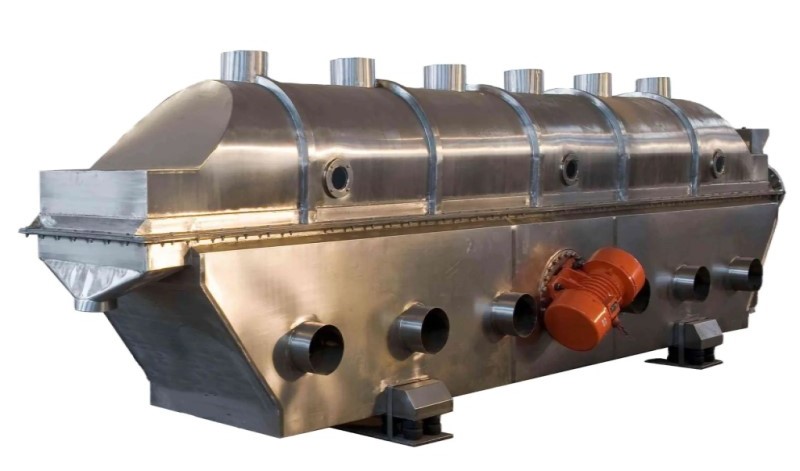

Vibrating fluidized bed dryer, abbreviated as vibrating fluidized bed, is a new type of fluidized bed high-efficiency drying equipment suitable for drying granular and powdery materials. It has the advantages of easy operation, energy saving, and environmental protection. ZLG vibrating fluidized bed dryer is a high-performance drying machine by Sinonine which combined with the actual needs of drying equipment market and which many technical improvements has been made.

Working principle of vibrating fluidized bed dryer

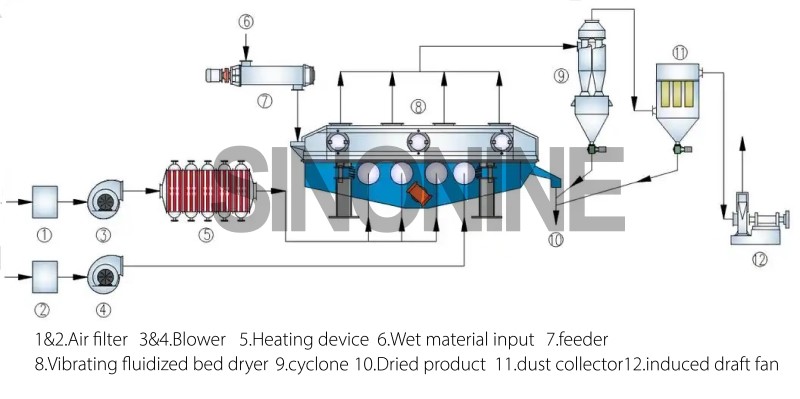

The blower filters the ambient air through primary and medium efficiency air filters, heats it to the set temperature through a steam heat exchanger, and finally enters the bottom of the fluidized bed dryer through a pipeline as a material fluidization and drying heat source. The wet material enters the bed plate (porous plate) inside the machine from the inlet of the bed body. Under the excitation force of the vibration motors on both sides of the fluidized bed, the material is thrown forward continuously in a horizontal direction. The hot air passes through the bed plate (porous plate) and comes into contact with the wet material. The wet material is suspended in the hot air, producing a mixed bed layer of material particles and hot air, like liquid boiling, and transferring heat and moisture between the material and the hot air. After heat exchange under the action of the induced draft fan, the hot air carries water vapor and small material particles and is discharged from the outlet of the induced draft fan after dust removal by the cyclone or bag dust collector.

After the material is dried, it continues to move forward. Cold air is commonly used at the bottom of the fluidized bed dryer, and a partition is made inside the lower bed of the fluidized bed to distinguish between cold air and hot air. After the material comes into contact with the cold air, it undergoes cold and hot exchange, resulting in a decrease in material temperature and achieving the desired effect. Finally, it is discharged from the discharge port and shares a dust collector and induced draft fan with the drying section.

When the material is thrown forward continuously on the bed plate (porous plate), a small portion of small particles will fall from the porous plate onto the bottom plate of the fluidized bed dryer. The bottom plate is parallel to the bed plate (porous plate) and under the action of vibration force, the material is thrown forward continuously in a horizontal direction. Finally, it is automatically discharged from the discharge port of the fluidized bed dryer.

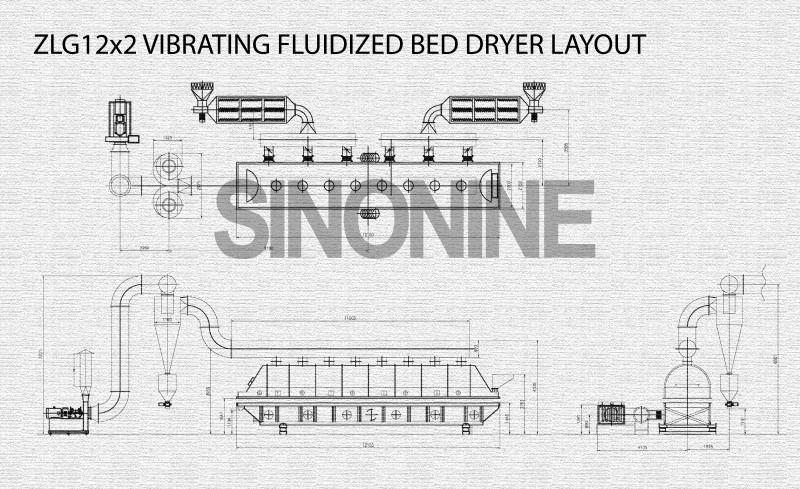

Following is the layout of vibrating fluidized bed dryer

Features of vibrating fluidized bed dryer

1.The vibration source of the vibrating fluidized bed is driven by a vibration motor, which runs smoothly, is easy to maintain, has low noise, and has a long service life.

2.Uniform fluidization, no dead gaps or blow through phenomena, can obtain uniform dry products.

3.The vibrating fluidized bed has good adjustability and a wide applicability. The thickness of the material layer, the speed of movement inside the machine, and the full amplitude can be infinitely adjusted.

4. Vibrating fluidized bed has minimal damage to the surface of materials. It can be used for drying fragile materials and does not affect the working effect even when the material particles are irregular.

5.The vibrating fluidized bed adopts a fully enclosed structure, effectively preventing cross infection between materials and air, and ensuring a clean working environment.

|  |

Application of vibrating fluidized bed dryer

The vibrating fluidized bed dryer is suitable for drying and cooling powdered and granular materials in industries such as chemical, pharmaceutical, food, dehydrated vegetables, grains, and minerals. For example citric acid, monosodium glutamate, borax, ammonium sulfate, compound fertilizer, shredded radish, soybean meal, distiller's grains, seeds, slag, sugar, etc.

|  |

Specification of vibrating fluidized bed dryer

Model | Bed area(m2) | Temperature of inlet air (℃) | Temperature of outlet air (℃) | Bed width (mm) | Weight (kg) | Power (kw) |

ZLG3x0.30 | 0.90 | 70-140 | 40-70 | 300 | 1250 | 0.8x2 |

ZLG4.5x0.60 | 2.7 | 70-140 | 40-70 | 600 | 1910 | 1.1x2 |

ZLG6x0.75 | 4.5 | 70-140 | 40-70 | 750 | 2340 | 2.2x2 |

ZLG7.5x0.9 | 6.75 | 70-140 | 40-70 | 900 | 4140 | 3.0x2 |

ZLG7.5x1.2 | 9.0 | 70-140 | 40-70 | 1200 | 5190 | 3.7x2 |

+86-25-58875679

+86-25-58875679 +86-18118821087

+86-18118821087