What is a rotary vaporization flash dryer for sale?

The rotary flash vaporization dryer is a new and high- efficiency fluidified drying equipment which is researched and

developed for the sake of overcoming the low-efficiency and high-consumed static drying. It combines the advantages of ordinary fluidified drying such as air stream drying, also with a reasonable design structure and wonderful performance, to realize the target of high efficiency and low energy consumption. The dryer is widely used for drying flame retardant, molecular screen, Rubber and plastics auxiliaries, pigment dyestuff, fine chemicals, animal feed.

How to a rotary flash vaporization dryer work?

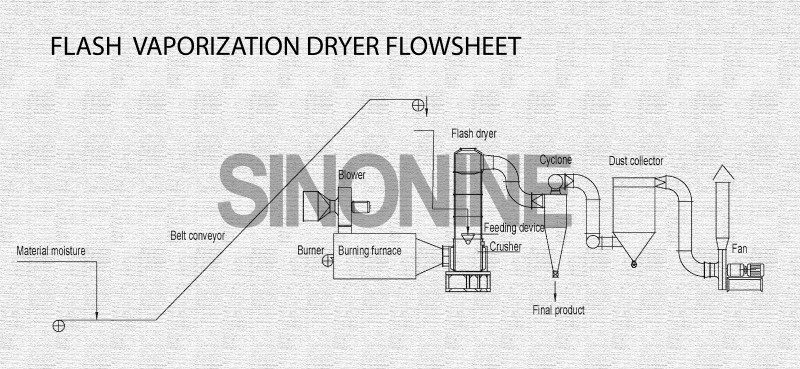

Hot air enters into stirring and crushing chamber from the bottom of dryer with suitable speed. It exerts strong shearing,

blowing, floating and rotating effect to material. Therefore raw material is particled and strengthens the heat exchange. At the bottom of dryer, the large damp particles is mechanical crushed, little particles with low moisture will flow up with revolving air stream. during the period of lifting, it is dried deeply. Because both of air and solid flow in high relative speed, so it strengthen the heat transferring effect. Thus this dryer has high drying efficiency.

What is a rotary flash vaporization dryer used for?

Organics: lauric acid septum, benzoic acid, benzoic acid, sodium oxalate, cellulose acetate, organic pigments, etc. Dyes: anthraquinone, black iron oxide, indigo pigment, butyric acid, titanium hydroxide, Zinc sulphide, various azo dye intermediates. Inorganic substances: borax, calcium carbonate, hydroxide, copper sulfate, iron oxide, barium carbonate, antimony, iron oxide, barium carbonate, trioxide, and so on. Iron oxide, barium carbonate, antimony trioxide, various metal hydroxides, various heavy metal salts, and synthetic cryolite. Foodstuffs: soy protein, dextrinised starch, wine trough, wheat sugar, wheat starch, etc.

Features of rotary vaporization flash dryer

1.There are many kinds of feeding device for choosing, and feeding is continuous and steady, it won't have aggregation.

2.The material will not go bad in high temperature at the bottom of dryer where there is cooling device.

3.There are air seal and shaft cooling device, to increase working life of transmission part.

4.There is special device for air distribution, it get will get balance inside.

5.There are rotational flow plate and grading round inside the drying chamber. controling the moisture and size of material available.

6.Because wind circle speed inside the drying chamber is high, and the staying time of material is short, can avoid

material sticky on the inner surface and heat sensitivity material going bad.

Specification of rotary vaporization flash dryer

Model | Barrel diameter(mm) | Main machine dimensions(mm) | Main machine power(kw) | Treatment wind capacity(m³/h) |

XSG-2 | 200 | 250×2800 | 5-9 | 300-800 |

XSG-3 | 300 | 400×3300 | 8-15 | 600-1500 |

XSG-4 | 400 | 500×3500 | 10-17.5 | 1250-2500 |

XSG-5 | 500 | 600×4000 | 12-24 | 1500-4000 |

XSG-6 | 600 | 700×4200 | 20-29 | 2500-5000 |

XSG-8 | 800 | 900×4600 | 24-35 | 3000-8000 |

XSG-10 | 1000 | 1100×5000 | 40-62 | 5000-12500 |

XSG-12 | 1200 | 1300×5200 | 50-89 | 10000-20000 |

XSG-14 | 1400 | 1500×5400 | 60-105 | 14000-27000 |

XSG-16 | 1600 | 1700×6000 | 70-135 | 18700-36000 |

+86-25-58875679

+86-25-58875679 +86-18118821087

+86-18118821087