What is a three cylinder rotary dryer for sale?

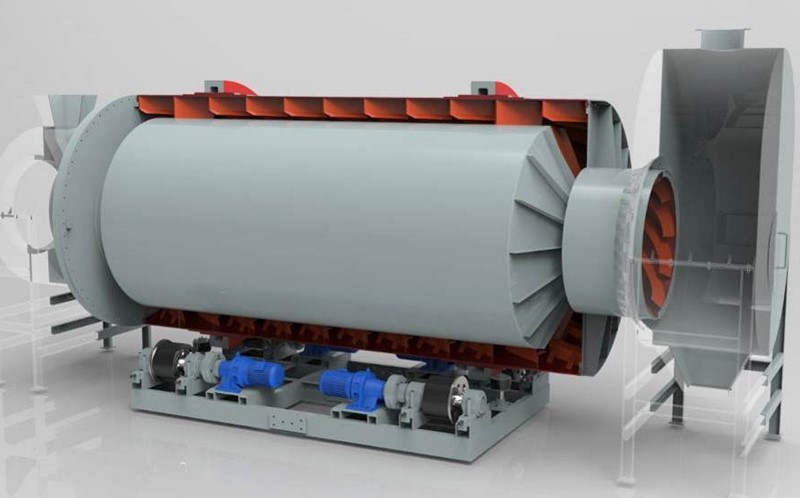

Three cylinder rotary dryer is a kind of high efficient triple pass rotary dryer, it has three layer rotary drum with a burning device. So, it is also called three drum rotary dryer, drum dryer or rotary dryer. We have many different types of this three cylinder rotary dryer so as to meet the drying material, you can also choose the natural gas, heavy oil, coal, petrol , biomass, diesel, LPG gas as fuel to provide heating to the triple pass rotary dryer.

It is the most popular and hot sale rotary dryer in the world.

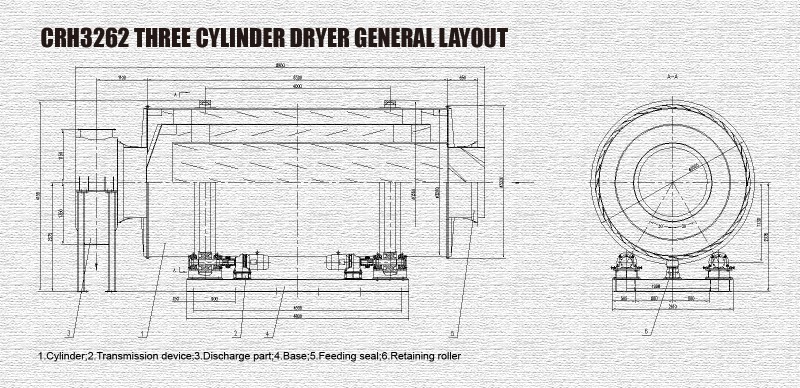

The naming rules of three cylinder rotary dryer are as follows, for example, CRH1530, CRH means the mark of triple pass rotary dryer, 15 means the outer diameter of the cylinder is 1500mm, 30 means the length of cylinder is 3000mm.The length and diameter of cylinder are not standard, they can be customized according to detail requirement.

|  |

How does a three cylinder rotary dryer work?

The work principle of a cylinder rotary dryer is following

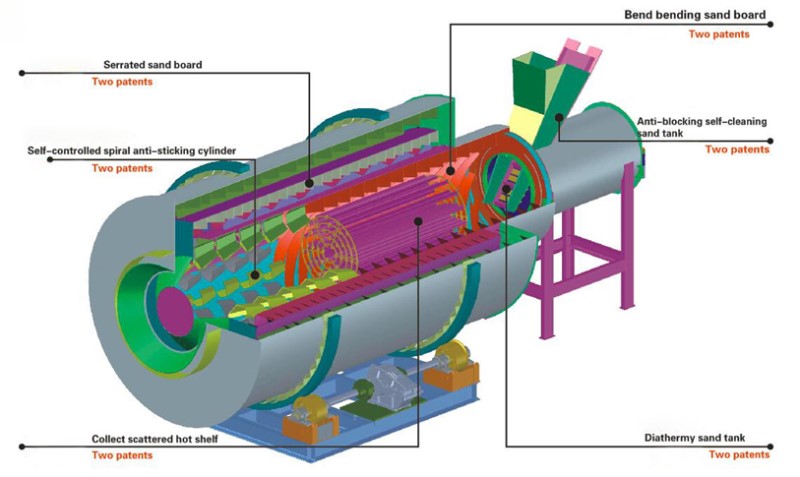

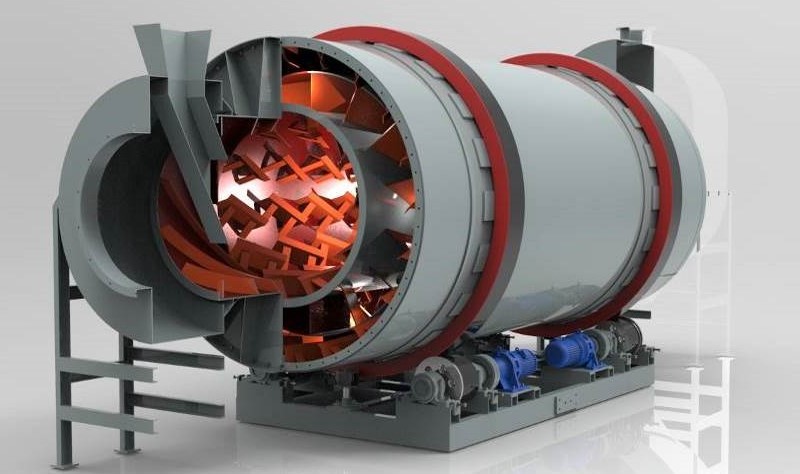

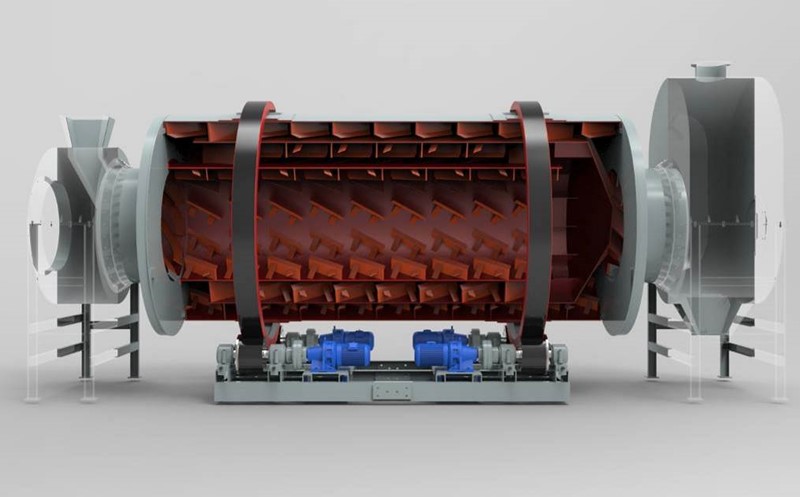

The wet material into the inner cylinder of the feeding end, is quickly pushed to the spiral lifting plate by the spiral guide plate. With the rotation of the cylinder, the spiral lifting plates set up in three cylinders make the materials lifted, at the same time, the materials continue to roll, scatter and do longitudinal motion.

At the same time the hot gas flow from the heat source successively enters the inner drum, the middle drum and the outer drum and to meet the material for a strong heat exchange. The thermal conductivity of metal plate is faster than that of materials, steel plate and lifting plate of cylinder of the first heat, then the heat by conduction and radiation transmitted to the material, the material is heated, when the temperature rises to the evaporation temperature, water vapor is separated from the material, discharged with the dust into the atmosphere, so as to achieve the purpose of drying materials. Below is a general layout of three cylinder rotary dryer which show three circuit rotary dryer.

Features of three cylinder rotary dryer

The three cylinder dryer produced by Sinonine has the following significant features and advantages.

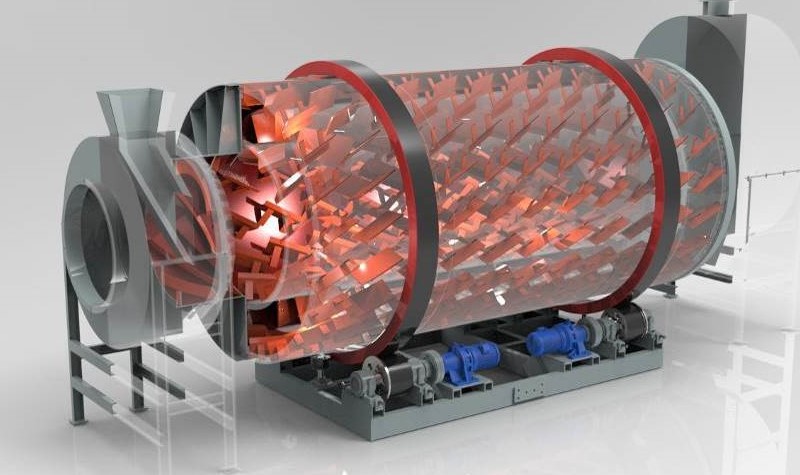

1.The overall size of the three cylinder rotary dryer is reduced by more than 30% compared to ordinary single-cylinder rotary dryers, thereby reducing external heat loss.

2.The thermal efficiency of the self-insulating dryer is as high as 80% (compared to only 35% for the ordinary rotary dryer), and the thermal efficiency is 45% higher.

3.Due to the compact installation, the floor space is reduced by 50%, and the infrastructure cost is reduced by 60%

4.The temperature of the finished product after drying is about 60-70 degrees, so that it does not need an additional cooler for cooling.

|  |

5.The three cylinder structure of the drying drum increases the contact area between the wet material and the hot air, which reduces the drying time by 48-80% compared with the traditional solution, and the moisture evaporation rate can reach 120-180 kg/m3, and the fuel consumption is reduced by 48-80%. The consumption is 6-8 kg/ton.

6.The drying of the material is not only carried out by the hot air flow, but also carried out by the infrared radiation of the heated metal inside, which improves the heat utilization rate of the whole dryer.

7.The overall size of the dryer is reduced by more than 30% compared to ordinary single-cylinder dryers, thereby reducing external heat loss.

8.The thermal efficiency of the self-insulating dryer is as high as 80% (compared to only 35% for the ordinary rotary dryer), and the thermal efficiency is 45% higher.

9.Due to the compact installation, the floor space is reduced by 50% and the infrastructure cost is reduced by 60%.

|  |

10.The temperature of the finished product after drying is about 60-70 degrees, so that it does not need an additional cooler for cooling.

11.The exhaust temperature is low, and the life of the dust filter bag is extended by 2 times.

12. The desired final humidity can be easily adjusted according to user requirements.

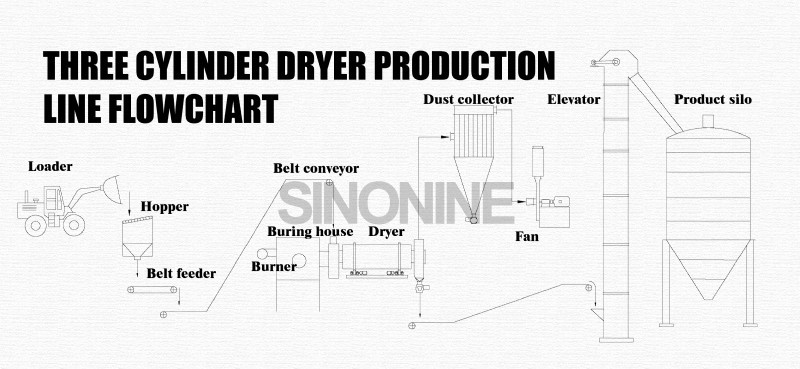

A whole three cylinder rotary dryer production line

The three cylinder dryer needs to be combined with auxiliary equipment to form a drying production line, which includes wet material hopper, belt feeder belt conveyor, burner, burning chamber, dust collector, finished product silo etc. The following is a commonly used three cylinder dryer production line flowchart.

How to select a suitable triple pass rotary dryer?

There are several tips for you as reference when you select a set three cylinder rotary dryer:

1.The raw material will be dried.

It is an important factor to be considered of the material features in the cylinder rotary dryer. Because different factors are considered for drying different raw materials.

2.The raw material water content in percent.

The original water content of the material determines the amount of energy consumption and also affects the operation of the rotary dryer. For materials with high moisture, we recommend physical dewatering first and then drying to save energy.

3.Product water content requirement

The min water content from three cylinder rotary dryer can reach below 0.5%, less moisture means longer drying time and heat consumption. We need to understand the appropriate moisture requirements for the final product in order to configure the appropriate model of rotary dryer.

4.Heating resource and fuel

The three cylinder rotary dryer requires a heat source to complete the drying process, so it is necessary to understand the type of heat source. Fuel options include natural gas,LPG gas, coal, diesel, heavy oil, gasoline, biomass etc.

|  |

5.The capacity

That means how many cubic meters or tons per hour you want this rotary dryer to process. Based on the capacity, we will decide small rotary dryer or large rotary dryer is suitable for you.

6.Ambient temperature

The work performance of rotary dryer will be affected if the working ambient temperature is too low. The rotary dryer for sale will be equipped with bigger volume cylinder or larger burner to compensate for heat loss.

What is the price of three cylinder rotary dryer for sale?

As a mature manufacturer of rotary dryers, Sinonine designed this series three cylinder rotary dryer which is suitable for different projects. It is equipped famous brand components such as electric motor, burner, bearings, reducer and electric cabinet etc. This three cylinder rotary dryer can be used to dry the powder and solid material with high water content. It is also called energy saving triple pass dryer with three circuits.

For the three cylinder rotary dryer for sale, Sinonine can provide you with different models with capacity from 1 t/h to 100t/h, and the length of rotary dryer cylinder, fuel heating device are different either. So, the price of different types three cylinder rotary dryer for sale is also different.

We would like to know your exact requirement, and recommend you a suitable three cylinder rotary dryer and drying production line. Then give you a best price in China for the rotary dryer.

|  |

Three cylinder rotary dryer manufacturing

Sinonine selects high-quality raw materials and accessories, adopts advanced processing technology, and ensures that every rotary dryer has high quality. From design, raw material selection, manufacturing, debugging, every step is meticulously carried out to complete excellent drying operations.

|  |

|  |

Three cylinder rotary dryer Goods Delivery

Based on good quality and decades of experience, the three cylinder rotary dryer which is manufactured by Sinonine was exported to different countries. The cylinder rotary dryer will be packed and loaded in our factory, and then be shipped to our clients safe and sound.

|  |

|  |

Specification of Three cylinder rotary dryer

Model | Cylinder dia. (mm) | Cylinder length (mm) | Rotating speed (r/min) | Volume (m³) | Drying capacity (t/h) | Power (kw) |

CRH1520 | 1500 | 2000 | 3-10 | 3.5 | 3-5 | 4 |

CRH1530 | 1500 | 3000 | 3-10 | 5.3 | 5-8 | 5.5 |

CRH1840 | 1800 | 4000 | 3-10 | 10.2 | 10-15 | 7.5 |

CRH1850 | 1800 | 5000 | 3-10 | 12.7 | 15-20 | 5.5*2 |

CRH2245 | 2200 | 4500 | 3-10 | 17 | 20-25 | 7.5*2 |

CRH2658 | 2600 | 5800 | 3-10 | 31 | 25-35 | 5.5*4 |

CRH3070 | 3000 | 7000 | 3-10 | 49 | 50-60 | 7.5*4 |

+86-25-58875679

+86-25-58875679 +86-18118821087

+86-18118821087